What factors affect the forging process of Barn Door Handle?

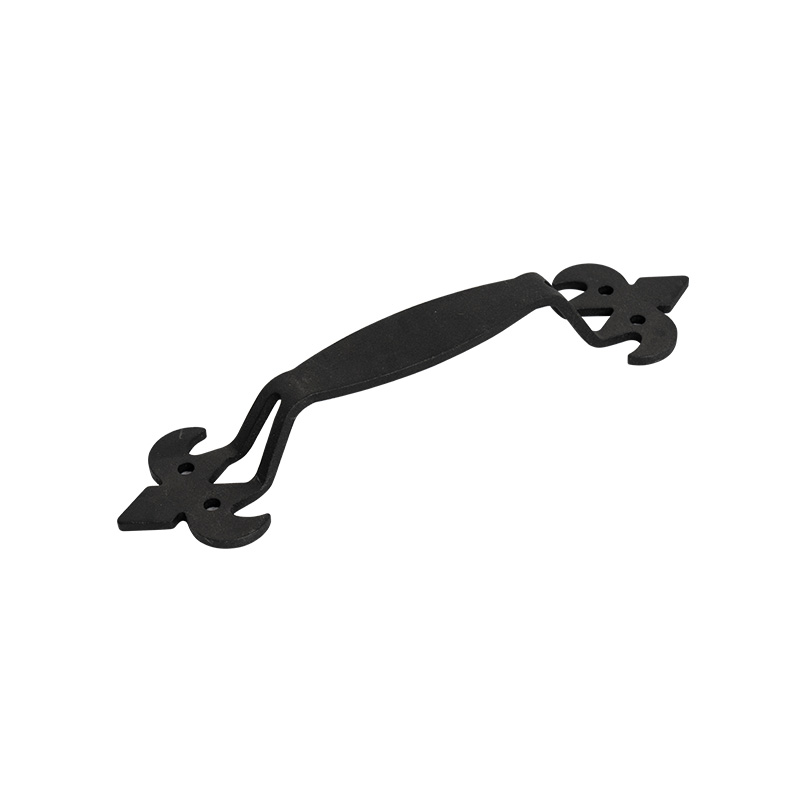

Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. has always adhered to the excellent material science, precision manufacturing technology and unlimited innovation spirit to continuously meet the needs of global customers for high-quality hardware products. Since the establishment of the company, we have accumulated rich experience in the hardware industry, with advanced production equipment and professional R&D team, committed to providing customers with efficient and reliable solutions. The Barn Door Handle series products are one of our company's products. This series of door handles has exquisite appearance and excellent performance in function and durability. As a company focusing on precision manufacturing, we are well aware that the forging process has a decisive influence on product quality. So, what factors affect the forging process of Barn Door Handle?

1. The first step of the forging process is material selection, and different materials have a direct impact on the final performance of the product. Commonly used materials include stainless steel, aluminum alloy, brass, etc. When Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. produces Barn Door Handle, it gives priority to stainless steel and aluminum alloy materials with strong corrosion resistance, high strength and easy processing according to the product's use environment and customer needs. The composition, hardness, ductility and other characteristics of the forging material will affect the plasticity during the forging process and the durability of the final product.

2. Temperature is one of the important factors affecting the forging process. Different metal materials will show different plasticity and toughness at different temperatures. In the process of forging Barn Door Handle, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. must strictly control the heating temperature to ensure that the metal maintains sufficient ductility during forging and does not become brittle due to overheating. Taking stainless steel as an example, it has the best forging performance between 1100°C and 1250°C. Through precise temperature control, we can ensure that each batch of door handles has excellent mechanical properties.

3. The way of applying pressure during the forging process is also a key factor affecting product quality. We usually use free forging and die forging. Free forging is mainly used for small-batch production. It is flexible and can be customized according to customer needs. Die forging is suitable for mass production. Through special molds, the size and shape of each Barn Door Handle can be highly consistent. The advantage of this method is that the internal structure of the product is more compact and the mechanical properties are more superior.

4. The forging process of Barn Door Handle usually includes heating, pre-forging, final forging, annealing and surface treatment. Each link has a profound impact on product quality. First, the metal raw material is heated to an appropriate temperature to make it have good plasticity. Then, in the pre-forging stage, preliminary forming operations are performed. In the final forging stage, the metal is further processed to the final shape. After forging, the product usually needs to be annealed to eliminate the stress generated during the forging process, thereby improving its toughness and stability. Finally, we will perform surface treatment on the door handle, such as electroplating or painting, to enhance its corrosion resistance and improve its appearance.

5. The pressure applied during the forging process directly determines the density and strength of the product. Too low pressure may cause pores or cracks inside the material, affecting the strength and durability of the product; while too high pressure may cause excessive deformation or fracture of the material. Therefore, the forging pressure must be reasonably selected according to the characteristics of the material and the specific requirements of the product. When we produce Barn Door Handle, we will adjust the pressure of the forging equipment according to the characteristics of different materials to ensure the density and structural integrity of each product.

6. The mold design of Barn Door Handle directly affects the quality and efficiency of forging. Our company has an experienced mold design team. When designing the mold, they not only consider the shape, size and tolerance of the product, but also the durability and heat treatment process of the mold material. Through reasonable mold design, we can minimize material waste and improve forging efficiency. At the same time, precise mold design also ensures the consistency of the shape and size of each door handle, which is especially important for mass production.

7. The forging process is not the end. The quality of Barn Door Handle also depends on the subsequent processing. Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. usually needs to machine, grind and polish the semi-finished products after forging to ensure that the product surface is smooth and flawless. In addition, for some customers with special needs, we also provide personalized surface treatment services, such as anodizing, brushing, etc., so that the door handle has good mechanical properties and a unique appearance design.

8. In order to ensure that every Barn Door Handle can meet the high standards of customers, we carry out strict quality inspections during the production process. Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. precisely measures the dimensions of each product and tests its mechanical properties, such as tensile strength and bending strength. Through a series of testing methods, we ensure that every door handle shipped has excellent quality and stable performance.

9. In the process of forging Barn Door Handle, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. also pays attention to environmental protection and sustainable development. We try to reduce energy consumption and waste generation, and actively use recyclable materials to reduce the impact on the environment. In addition, the company's production process strictly abides by national environmental protection regulations to ensure that our products not only meet international quality standards, but also meet environmental protection requirements.

The forging process of Barn Door Handle is a complex and precise process, which is affected by many factors. The selection of materials, forging temperature, pressure control, mold design and other links play a vital role in the final quality of the product. Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. always upholds the spirit of craftsmanship and is committed to providing high-quality products to customers around the world. Each Barn Door Handle is the crystallization of our exquisite craftsmanship, which is both beautiful and practical, and can add a unique style to your home life.

English

English 中文简体

中文简体