What is the bearing installation process when manufacturing the pulley of Barn Door Slides?

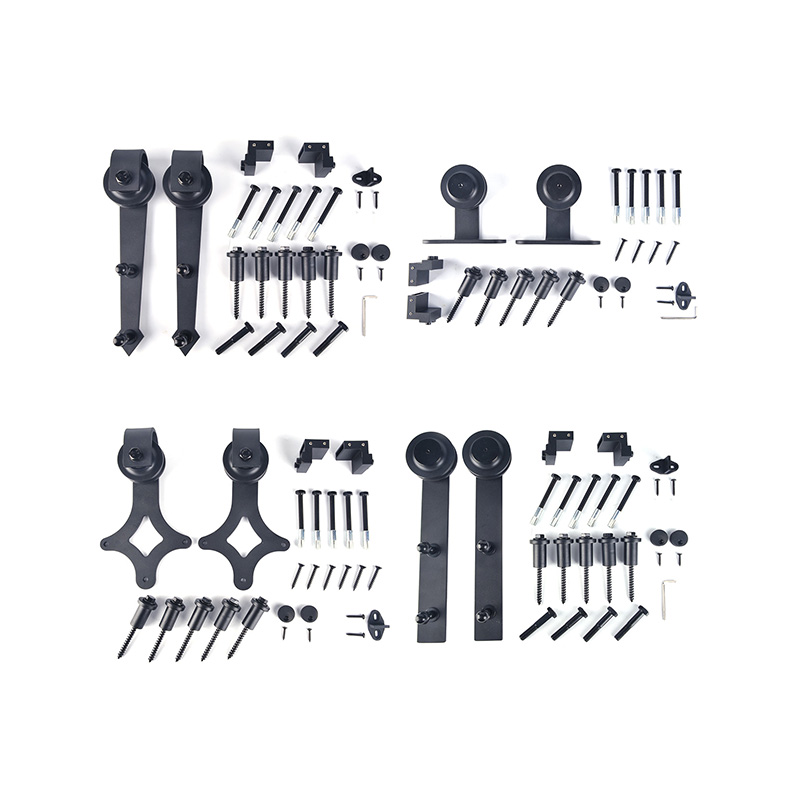

Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. has rich experience in the field of hardware product manufacturing, covering CNC processing, stamping products, metal lockers, household hardware, plastic products, standard fixed hardware and other fields. We have won the trust and praise of our customers with superb material science and technology, rigorous manufacturing process and continuous innovation. The following will introduce our company's Barn Door Slides series products, one of the most important steps - the bearing installation process of the pulley.

Barn Door Slides is an increasingly popular sliding door system in modern home decoration. It can save space and add a unique aesthetic to interior design. In the entire slide system, the role of the pulley is crucial. The pulley needs to bear the weight of the door and ensure that the door can slide smoothly and smoothly. The operating performance of the pulley is directly related to the use experience and life of the slide system, and the bearing, as the core component of the pulley, determines the sliding effect of the pulley.

High-quality bearings can significantly reduce the friction of the pulley on the slide rail, making the door smoother and quieter when moving, while extending the service life of the pulley. Therefore, in the manufacturing process of the Barn Door Slides pulley, the installation of the bearing is particularly important.

1. Before installing the bearing, choose the right type of bearing. For the pulley of Barn Door Slides, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. usually uses ball bearings. Ball bearings are the best choice for smooth sliding of the pulley due to their excellent load-bearing capacity and low friction characteristics. The ball bearings we choose have the following characteristics:

High precision: Ensure that the pulley does not shake during the sliding process. The ball bearings of Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. are extremely accurate and can ensure the smoothness of sliding.

Durability: Our ball bearings are made of high-strength materials, which can maintain excellent performance during long-term use and are not easy to wear or deform.

Corrosion resistance: Since Barn Door Slides are usually used in different indoor and outdoor environments, the bearings we choose have good corrosion resistance, can adapt to environments with high humidity, and extend their service life.

2. Bearing installation is one of the key steps in pulley manufacturing, involving multiple processes, including bearing pretreatment, installation, fixing and testing. The following is a detailed process of bearing installation in Barn Door Slides pulley manufacturing by Ningbo Haishu Dongxiang Precision Hardware Co., Ltd.

Bearing pretreatment: Before installing the bearing, the bearing needs to be pretreated. We will clean and lubricate each bearing to ensure that it is not affected by impurities during the assembly process.

Cleaning: Even high-precision ball bearings are inevitably contaminated with dust or other impurities during production and transportation. We use special cleaning agents to thoroughly clean the bearings to ensure that there are no particles or dirt inside and on the surface, which helps the bearings remain smooth during use.

Lubrication: After cleaning, we will add an appropriate amount of lubricating oil to the bearings. Lubricating oil not only reduces the friction between the balls, but also prevents the bearings from wearing due to lack of lubrication during long-term use.

The design of the pulley requires that the bearing and the hub are precisely matched to ensure that the pulley remains stable and balanced when sliding on the slide rail. We use high-precision CNC equipment to process the pulley to ensure the accuracy of the bearing installation position. Before installing the bearing, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. will test the pulley to ensure that the size and shape of its bearing installation groove perfectly match the bearing. We pay special attention to the following points:

Concentricity: The concentricity requirements of the bearing and the pulley are very high. If the concentricity deviates during the installation process, it will cause the pulley to wobble when sliding, affecting the overall smoothness and safety of the slide rail system.

Dimensional tolerance: The dimensional tolerance of the bearing groove must be controlled within a very small range, neither too loose nor too tight. Too loose will cause the bearing to loosen during use, and too tight may cause the bearing to deform or damage.

After ensuring that the size and position of the bearing and pulley are accurate, we will use automated assembly equipment to install the bearing. Automated equipment can ensure that the bearing of each pulley can be installed in place with consistent force and precision, reducing the error caused by manual operation.

Assembly force control: The assembly equipment we use has a precise force control function, which can ensure that no excessive pressure is applied to the bearing during the installation process. Excessive assembly force may cause damage to the internal structure of the bearing, which will affect its service life.

Accurate positioning: Through automated assembly equipment, we can ensure that each bearing can be accurately positioned to maintain perfect concentricity between the bearing and the pulley. This is essential to ensure the smooth operation of the pulley.

After the bearing is installed in place, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. also needs to fix and test it to ensure that the bearing does not loosen during use.

Fixing process: In order to ensure that the bearing remains stable in the pulley, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. uses a press-fit process to firmly fix the bearing in the pulley. At the same time, for some pulleys with special structures, we will also use locking rings or welding processes to further strengthen the fixing of the bearing.

Inspection: After the bearing is installed and fixed, we will conduct strict quality inspections on each pulley. We use high-precision testing equipment to test the concentricity, installation strength and fixing effect of the bearing and the pulley to ensure that the bearing of each pulley can run smoothly on the slide rail.

After the bearing is installed, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. will perform a sliding test on the pulley. The purpose of the sliding test is to ensure that the bearing runs smoothly in the pulley and the pulley can slide on the slide rail without obstacles. We simulate the actual use scenario of the slide rail system and perform repeated sliding tests on the pulley to test its sliding performance and durability.

Smoothness test: Test whether the pulley can maintain smooth sliding on the slide rail without jamming or blocking.

Noise test: The operation of the bearing directly affects the noise performance of the pulley. We use noise tests to ensure that the pulley does not generate excessive friction noise during sliding.

Durability test: Through long-term and high-intensity sliding tests, we can detect whether the pulley can maintain its smoothness in long-term use and ensure its durability and stability.

The bearing is the core component of the Barn Door Slides pulley. Its installation process determines the smoothness and service life of the pulley. Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. strictly controls every link in the bearing installation process to ensure that each pulley can meet high standards of quality. Through the precise bearing installation process, our Barn Door Slides products can provide customers with a long-lasting, stable and smooth use experience. Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. will continue to uphold the attitude of excellence and be committed to providing global customers with better hardware products.

English

English 中文简体

中文简体