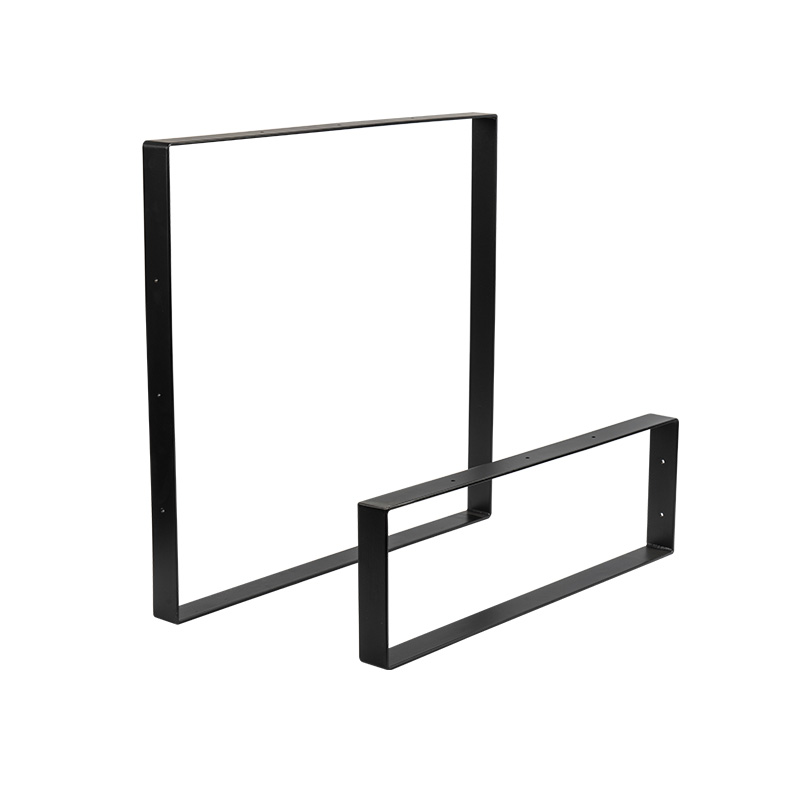

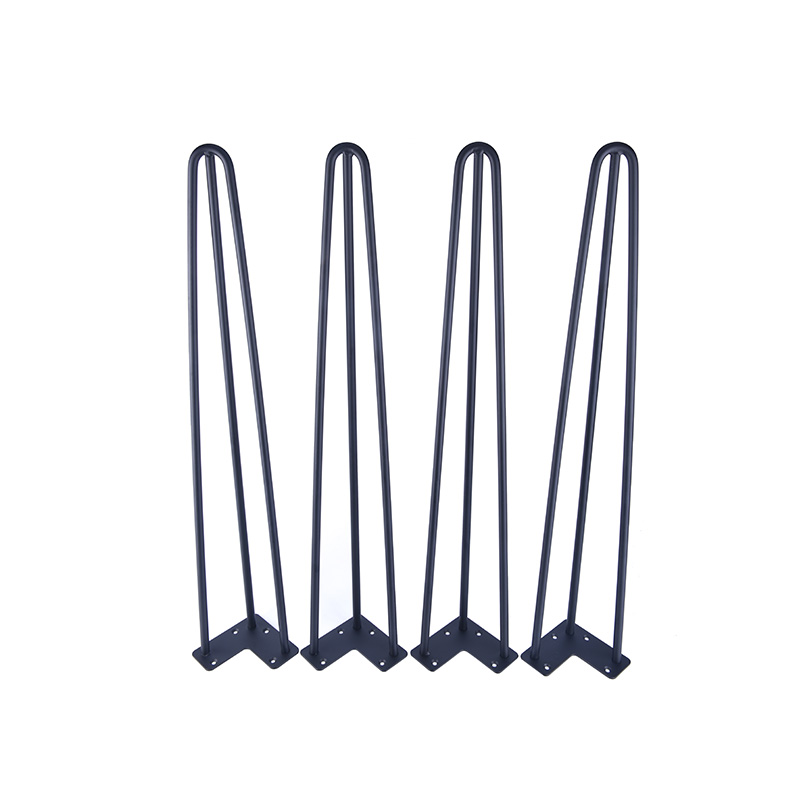

Welding Metal Furniture Table Legs using MIG welding process

Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. has been committed to providing high-quality hardware products to customers around the world. We have rich production experience and a wide range of product lines covering CNC processing, stamping products, metal lockers, household hardware, plastic products, fasteners and standard fixing hardware. Each product undergoes strict quality control to ensure its durability and stability. The following is an introduction to the production process in the MIG welding process of the Welding Metal Furniture Table Legs series of products.

1. In the process of producing and welding metal furniture table legs, it is necessary to first design the product and select materials. Commonly used materials include carbon steel, stainless steel and aluminum alloy, which can not only ensure the strength of the product, but also have good processing performance.

Carbon steel is suitable for load-bearing furniture and has good compressive strength. It is usually used for industrial-style furniture table legs. Stainless steel is widely used in high-end household furniture due to its corrosion resistance and beautiful surface. Aluminum alloy is often used in modern furniture design because of its light weight.

After the design is completed, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. will develop a specific welding process based on the material properties and the structure and shape of the table legs. MIG welding technology has become our welding process because it is efficient, stable, and suitable for mass production.

2. MIG welding is one of the most common metal arc welding processes. During the welding process, the welding wire is used as an electrode and filler material. It is automatically fed into the welding area through a welding gun. The arc melts the welding wire and the workpiece together to form a weld. At the same time, the welding area is protected by an inert gas (such as argon or carbon dioxide) to prevent oxidation and contamination.

The main advantages of MIG welding are as follows.

Fast welding speed: Due to the continuous feeding of the welding wire, the welding efficiency is high and it is suitable for mass production.

High welding quality: The weld is uniform, the structure is strong after welding, and the crack resistance is strong.

Easy operation: The process is highly automated, reducing manual errors, and is suitable for welding metal furniture table legs of various complex shapes.

3. The process flow of MIG welding is as follows.

Before welding begins, the workpiece must be cleaned first. Any residual grease, scale or dust will affect the welding quality, so it is necessary to ensure that the welding area is clean and smooth. We usually use mechanical grinding or chemical treatment to treat the surface of the material.

At the same time, it is necessary to prepare welding wire and inert gas suitable for the welding material. Carbon steel usually uses welding wire containing a small amount of carbon, stainless steel uses corrosion-resistant welding wire, and aluminum alloy welding requires special aluminum welding wire. The choice of inert gas will also vary depending on the material. For example, a mixture of carbon dioxide and argon is often used for carbon steel welding, while pure argon is more suitable for aluminum alloy welding.

Before officially starting welding, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. will set the welding parameters according to the thickness of the material, the type of weld and the welding position. The main parameters include current intensity, voltage, welding speed and gas flow. These parameters directly affect the quality and strength of the weld, so they must be accurately debugged.

Current intensity: The current during welding determines the depth of the weld and the size of the molten pool. Thicker materials require higher currents.

Voltage: Voltage affects the stability of the arc. Too low voltage will cause arc instability, and too high voltage may cause spatter.

Welding speed: The welding speed is closely related to the appearance and quality of the weld. Too fast speed may result in insufficient welds, while too slow speed may result in excessive welds, affecting the appearance.

Gas flow: The appropriate gas flow can effectively protect the welding area and avoid oxidation, but too much gas flow will cause unstable welding.

The actual operation of MIG welding is completed by professional welders or automated welding equipment. Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. uses advanced automated welding equipment to accurately control the welding path and speed to ensure consistent and beautiful welds for each table leg.

During the welding process, the welding wire is automatically fed into the welding area through the welding gun, and the arc is formed between the welding wire and the workpiece, melting the welding wire and the metal workpiece together. Inert gas is ejected around the welding gun to protect the molten area from oxygen and impurities in the air.

Since the structure of metal furniture table legs is usually complex, the welding workers or equipment operators of Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. need to be very skilled in controlling the welding angle and welding path to ensure the uniformity and strength of the weld. For thicker table legs, we usually use multi-layer welding technology to ensure the depth and strength of the weld.

After welding, there are usually certain bulges or spatters in the weld area of the table legs. In order to ensure the beauty and smoothness of the table legs, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. will grind and polish the welds to make them flat and consistent with the surrounding surface.

According to customer needs, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. will also perform surface treatment on the table legs. This includes powder spraying, electroplating or painting to improve the product's anti-corrosion performance and appearance texture. Powder spraying can increase the wear resistance of the table legs and give them a matte or bright surface effect.

Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. is well aware of the importance of welding technology to the quality of metal furniture table legs. MIG welding technology, with its high efficiency, precision and stability, helps us produce high-quality, durable and beautiful furniture table legs. We always adhere to the concept of "quality first, customer first" and provide better products and services to global customers by continuously optimizing our welding technology. Whether it is industrial furniture, commercial furniture, or household furniture, our welded metal furniture table legs series products can add a combination of firmness and beauty to your space.

English

English 中文简体

中文简体