What is the stamping process of the Metal Stamping Parts series of stamping parts?

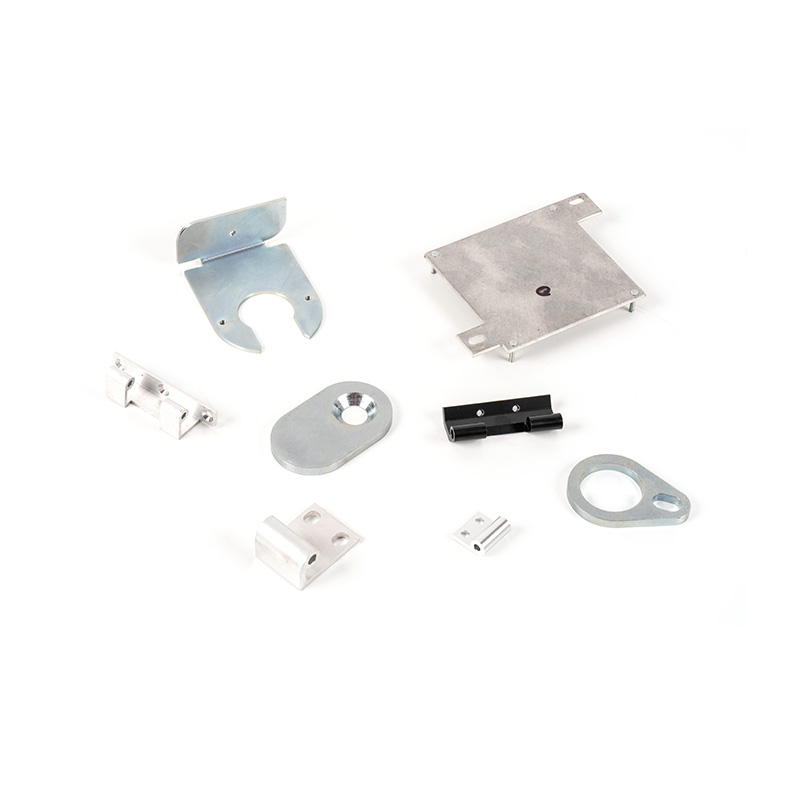

Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. is a professional hardware manufacturing company located in Ningbo, Zhejiang Province, and has always been committed to providing high-quality hardware products to customers around the world. We introduce advanced technology and equipment in the production process, and continue to innovate and optimize the production process with excellent material science and rich manufacturing experience. Our company has a wide range of product categories, covering CNC machined parts, stamping products, metal storage cabinets, home hardware, plastic products, PEM standard parts and standard fasteners. Metal Stamping Parts is one of our company's products. The following will introduce the stamping process and technical advantages of this series of stamping parts.

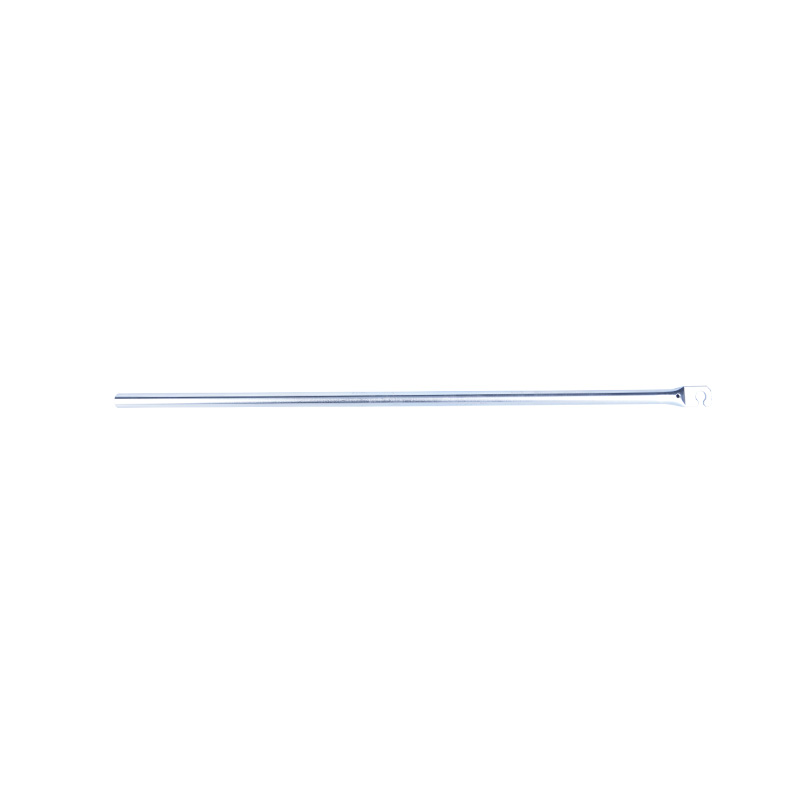

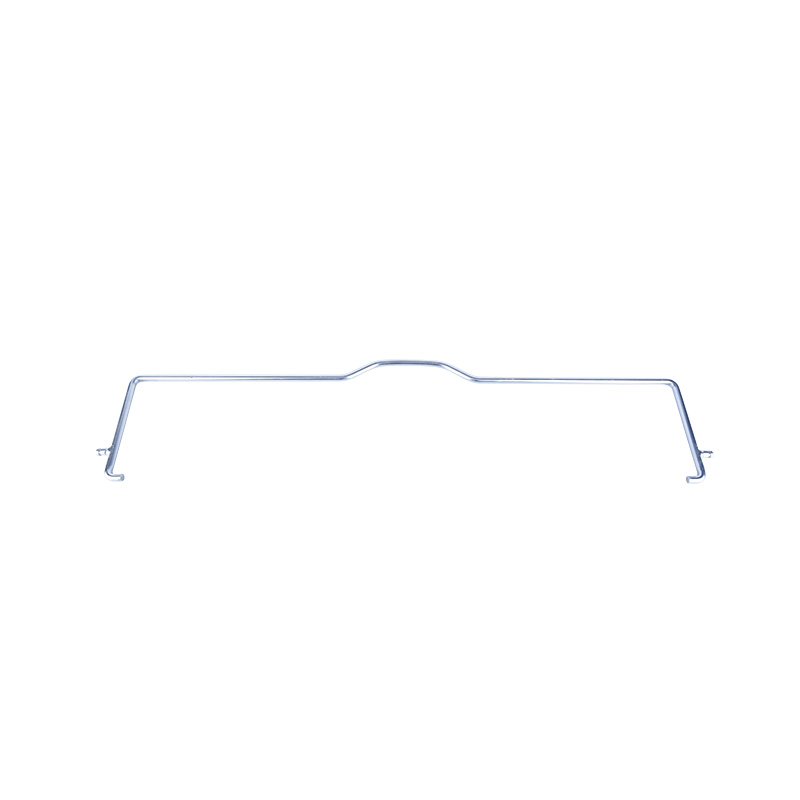

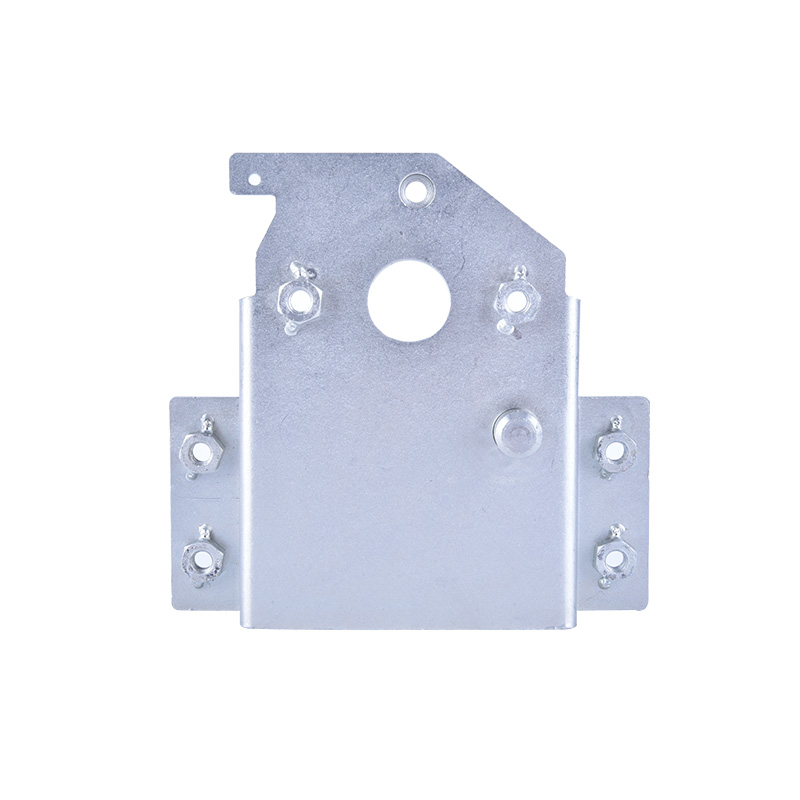

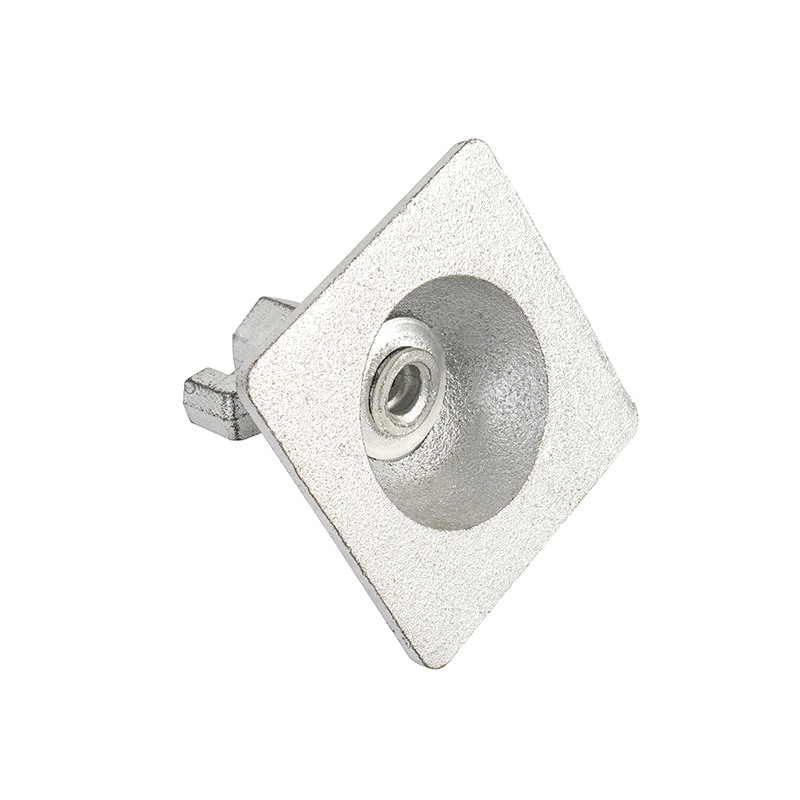

Metal stamping parts are an indispensable part of modern industrial production and are widely used in industries such as automobiles, electronics, home appliances, aviation, and medical devices. The metal stamping process uses punches and dies to plastically deform metal sheets to create parts of various complex shapes and sizes. The metal stamping parts produced by Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. have the characteristics of high precision, good strength and smooth surface, which meet the needs of different customers for high-quality parts.

1. The production process of metal stamping parts needs to go through a series of process steps, involving material selection, mold design, stamping forming, surface treatment and other links. Below we will introduce the key production processes of metal stamping parts in detail.

Material selection: The quality of metal stamping parts depends first on the selected materials. Commonly used stamping materials include carbon steel, stainless steel, aluminum, copper and its alloy materials. According to the performance requirements of the final product, such as tensile strength, corrosion resistance, machinability, etc., Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. will select the most suitable material for each project. For example, stainless steel materials are often used in occasions with high environmental requirements, such as parts of medical equipment and kitchen utensils, due to their strong corrosion resistance and superior mechanical properties. Aluminum alloy materials are widely used in automotive parts and electronic components due to their lightness and good conductivity.

2. The mold is the core of the metal stamping process. The design of the mold directly affects the precision, molding quality and production efficiency of the stamping parts. In the process of mold design, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. will fully consider the ductility, resilience and shape complexity of the material to ensure the product size is accurate and the deformation is uniform.

Mold manufacturing uses high-precision CNC machine tools and EDM technology to ensure the precision and durability of the mold. For parts produced in large quantities, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. will also design multi-station molds to improve production efficiency and reduce material transfer time between processes.

3. Stamping is the key step of the entire process. It processes the flat material into the required shape through the synergy of the punch and the mold. Our commonly used stamping processes include stretching, bending, punching, shearing, flanging, etc. According to the different requirements of the product, single-station stamping, multi-station stamping or continuous die stamping can be selected.

Stretching: The stretching process is used to manufacture deep concave parts, such as automobile fuel tanks, kitchen sinks, etc. This process requires the material to have good ductility and extremely high mold precision.

Bending: The bending process is used to bend metal sheets into a certain angle or shape, and is usually used for bracket parts in electronic equipment. The bending process needs to consider the resilience of the material to ensure the accuracy of the angle after forming.

Punching: The punching process punches holes in metal sheets through a die, and is often used for parts that require through holes, such as metal screens or ventilating plates.

Shearing: The shearing process is used to cut metal sheets and divide them into the required shape. We often use high-speed punching machines for shearing to ensure smooth and burr-free cutting edges.

4. After completing the stamping process, metal stamping parts may also need a series of post-processing processes to improve the surface quality and functional performance of the parts. These post-processing processes include deburring, polishing, heat treatment, electroplating, spraying, etc.

Deburring and polishing: Fine burrs may be generated on the edges of the parts during the stamping process. The deburring process can remove these burrs and ensure a smooth surface of the parts. For parts that require a high surface finish, we also perform polishing.

Heat treatment: Heat treatment process can change the internal structure of metal materials and improve the hardness and strength of parts. Especially for some parts that need to withstand high loads, heat treatment is a very necessary step.

Electroplating and spraying: In order to improve the corrosion resistance and appearance of stamping parts, we will perform electroplating or spraying according to customer needs. Commonly used electroplating materials include zinc, nickel, chromium, etc., which can effectively prevent parts from oxidation and corrosion during use.

5. In order to ensure the quality of each stamping part, Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. implements strict quality control measures during the production process. From raw material inspection, mold debugging to finished product inspection, each link is monitored by a professional quality inspection team. Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. uses high-precision measuring equipment, such as three-coordinate measuring machines, optical detectors, etc., to comprehensively test the size, surface quality and mechanical properties of stamping parts to ensure that each product meets customer requirements.

Ningbo Haishu Dongxiang Precision Hardware Co., Ltd. is always customer-oriented and provides high-quality metal stamping parts to customers around the world through advanced stamping technology. We have strong production capacity and a strict quality control system to ensure that every product meets the high standards of customers. In the future, we will continue to focus on innovation and technology improvement to create better metal stamping products and provide customers with excellent solutions.

English

English 中文简体

中文简体